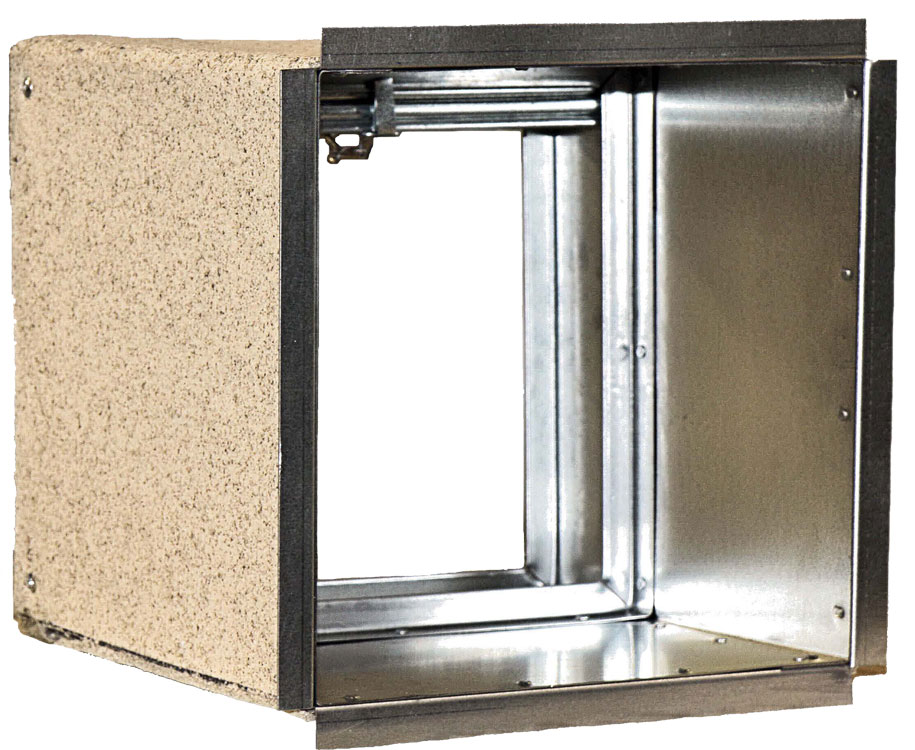

Rectangular cut-off fire dampers, with a single-plane cut-off partition, are the most frequently performed type by manufacturers. The main limitation of this type of flaps, for large cross-section cables, it is necessary to keep the minimum length of the straight line connected to the damper, due to the shut-off baffle, which, in the waiting position, protrudes beyond the body of the damper itself. In practice, in the case of large flaps, it is not possible to use a knee, offsets or reductions directly behind the flap, which can be a serious restriction on installation and additional costs. In addition, to maintain the declared fire resistance, the damper must be set in the building partition, with proper depth, called the brickwork border, obligatorily marked by each producer on the damper body. In situations, where it is necessary to use it just behind the wall, e.g.. knees, the hatch must be moved away from the wall, which makes it impossible to build it in while maintaining the boundary of the bricklaying. In such a situation, to maintain the fire resistance of the damper, it is necessary to make fireproof insulation in the fire resistance class required for the building partition, reaching up to the edge of the damper. Mounting solutions of this type, individual for each producer, must be included in the technical approval. Rectangular damper body, with a single-plane shut-off partition, It is most often made by manufacturers of steel sheet, with possible separation of the body with a divider made of fireproof material or fireproof board. In both cases it is possible to achieve the same fire resistance, and the diversity of the materials used is a consequence of the technological capabilities of individual producers. The shut-off partition is practically exclusively made of fireproof board, especially for dampers with a fire resistance of at least El 120, confirmed in the study. Please note, that the currently used fireproof boards have relatively low mechanical resistance, therefore also the dampers are devices, which require, in construction conditions, caution during assembly or transport.

Rectangular cut-off fire dampers, with a single-plane cut-off partition, are the most frequently performed type by manufacturers. The main limitation of this type of flaps, for large cross-section cables, it is necessary to keep the minimum length of the straight line connected to the damper, due to the shut-off baffle, which, in the waiting position, protrudes beyond the body of the damper itself. In practice, in the case of large flaps, it is not possible to use a knee, offsets or reductions directly behind the flap, which can be a serious restriction on installation and additional costs. In addition, to maintain the declared fire resistance, the damper must be set in the building partition, with proper depth, called the brickwork border, obligatorily marked by each producer on the damper body. In situations, where it is necessary to use it just behind the wall, e.g.. knees, the hatch must be moved away from the wall, which makes it impossible to build it in while maintaining the boundary of the bricklaying. In such a situation, to maintain the fire resistance of the damper, it is necessary to make fireproof insulation in the fire resistance class required for the building partition, reaching up to the edge of the damper. Mounting solutions of this type, individual for each producer, must be included in the technical approval. Rectangular damper body, with a single-plane shut-off partition, It is most often made by manufacturers of steel sheet, with possible separation of the body with a divider made of fireproof material or fireproof board. In both cases it is possible to achieve the same fire resistance, and the diversity of the materials used is a consequence of the technological capabilities of individual producers. The shut-off partition is practically exclusively made of fireproof board, especially for dampers with a fire resistance of at least El 120, confirmed in the study. Please note, that the currently used fireproof boards have relatively low mechanical resistance, therefore also the dampers are devices, which require, in construction conditions, caution during assembly or transport.

Maintaining fire integrity in the test requires the use of intumescent gaskets in the dampers, which are activated at a temperature of about 100 ° C. Please note, that the swelling gaskets are mounted by sewing on the cut-off partition or inside the body of the fire damper at the height of the partition, they are relatively susceptible to mechanical damage and occur very often, that they are damaged or torn off locally during assembly work. Beyond the risk, that the damper will not be able to maintain the required fire resistance under fire conditions, a torn off seal may cause blocking of the partition when changing the position of the damper. Such a situation, after installing the damper in the duct of ventilation ducts, can mean significant service costs. Therefore, it is recommended to carefully check the damper before connecting it, that the gasket is properly seated. Similar problems exist with the gaskets used to guarantee smoke tightness (S) clap, i.e. gaskets to keep the damper tight in "cold" conditions.

For assembly reasons and to ensure service access, the use of flaps is recommended, the control mechanism of which, after installing the damper, is located outside the building partition. Otherwise, it is necessary to leave an opening with irregular dimensions in the building partition or, when such was not made, the installation company must forge or cut a suitable slot in the building partition for the control mechanism. The damper mechanism remaining in the wall clearance also makes it difficult to embed in the damper. Additionally, when servicing the damper with the control mechanism located in the partition, service access is seriously limited and cumbersome. You should also pay attention, how manufacturers provide for the replacement of the thermal release. The best solution is to replace the trigger without the need for time-consuming damper revision, which in construction conditions takes a long time and is troublesome to unscrew. In all cases, when the works are carried out in stages or when the target functions of the premises and solutions in the field of fire alarms are unknown, the use of dampers with an evolutionary control system is of great importance. Such a solution makes it possible, at any time after installing the damper in the building and after installing additional accessories, transforming the automatic damper into a remotely controlled damper.